304 stainless steel chain belt for Drying, Washing, Tunnel Oven Equipment, metal mesh belt , Chain Driven Metal Mesh Belts, Straight Running Belts, Chain Weave Conveyor Belt

Description

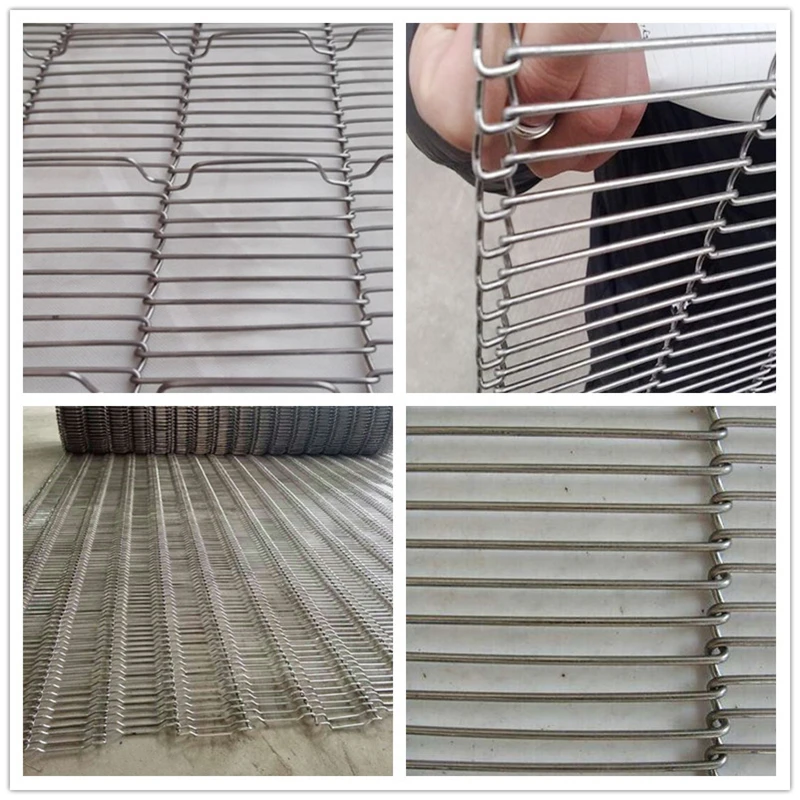

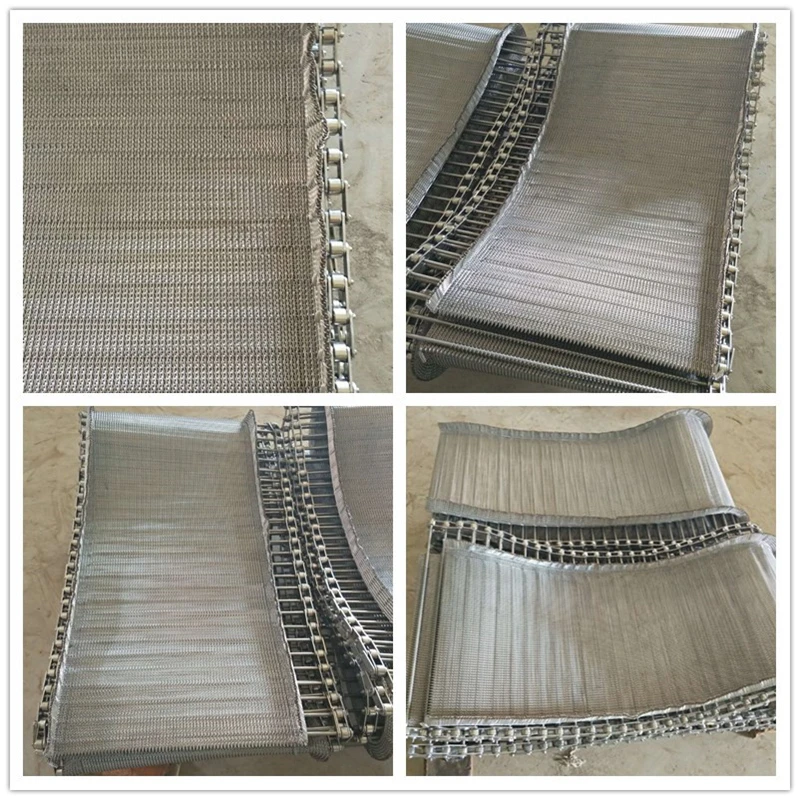

Stainless steel chain belt is a main conveyor form of transportation, is a wire conveyor belt to be attached to chain on both side. Belt and chain are synchronized running through an intermediate connecting rod.

Provide efficient operation in applications where friction drive belts are not adequate.

In cases such as travel-up inclines, under heavy loads, for long distances, through quenching liquids, cooking oils or other slippery conditions.

Chain driven mesh belt is also the only belts that are self supporting. It can provide efficient operation in applications where friction drive belt would not be desirable.

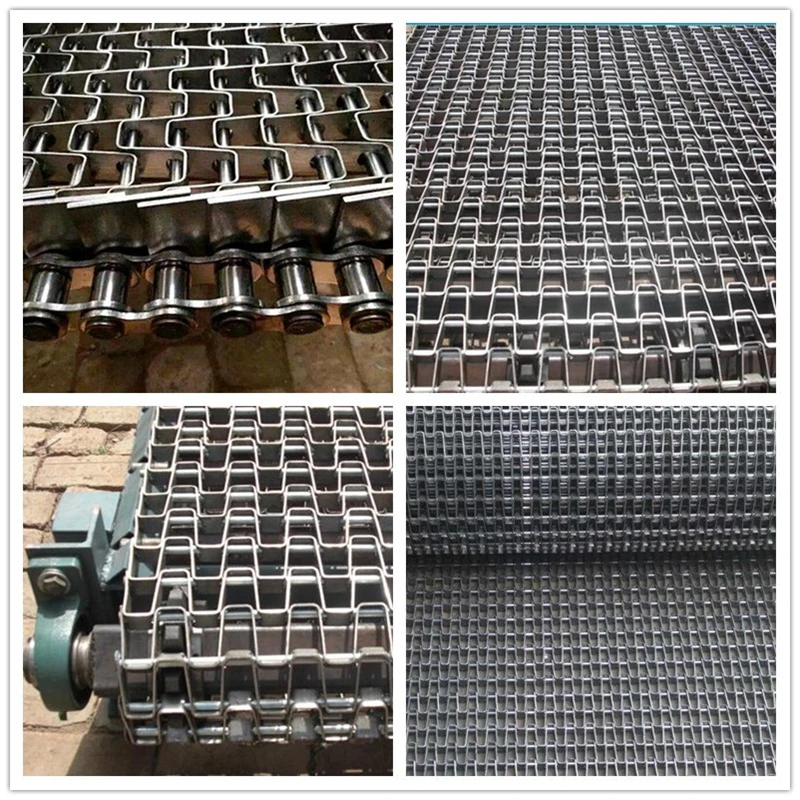

Any mesh can be used in a chain driven construction, but the selection is ma on the basis of what is needed to support the product. Balanced weave kind should be given first consideration, as it is economical and appropriate for most conditions.

1:the furface is flat , smooth , so that heavy loading can be transported

2:the allowable tension ig high , so that the belt can be used for processing under prssure

3:it is drived by sprocket , not occur

4:various typles of chain can be applied by ajusting belt pitch

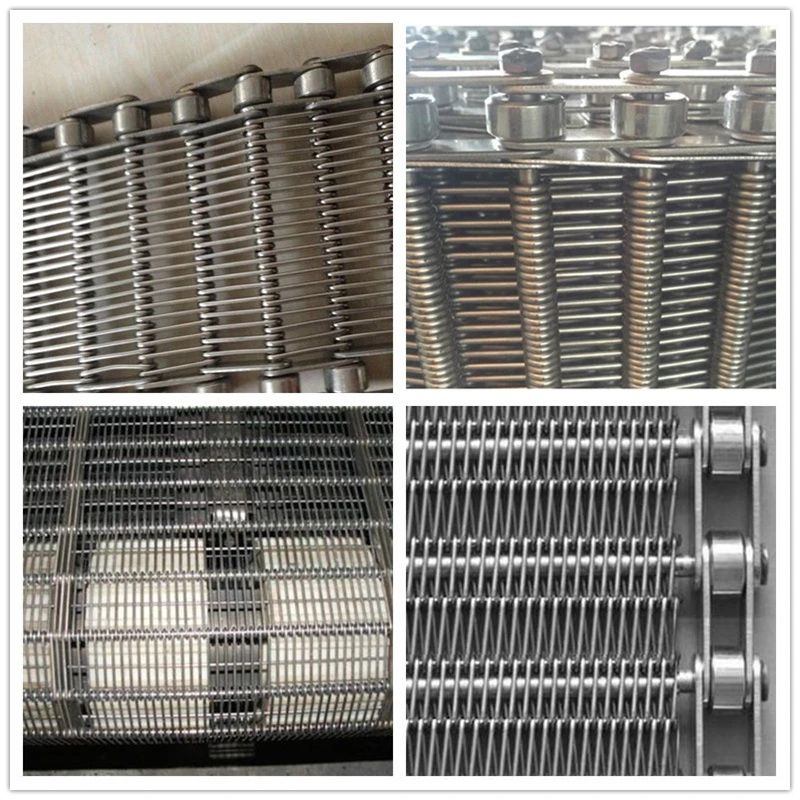

| size | material | wire diameter(mm) | spiral pitch(mm) | chain pitch(mm) | rod pitch (mm) | rod diameter(mm) |

| length xm x width 1035mm (steel chain) | ss304 | 1 | 3.175 | 31.75 | 190.5 | 1.2 |

| length xm x width 1225mm(steel chain ) | ss304 | 1.2 | 3.175 | 31.75 | 190.5 | 1.5 |

| lengthxm x width 1020mm(wothout chain) | ss304 | 1 | 3.175 | 12.7 | 1.2 | |

| lenghtxm xwidth1215mm(without chain) | ss304 | 1.2 | 3.175 | 12.7 | 1.5 |

Our 304 stainless steel chain belt or wire link belts are your ideal metal conveyor belts for light-to-medium transfers. Up to 86% proportion of open area provides maximum air-flow through and improve efficiency in cooling, heating, draining and drying performances. Smallest diameter end rolls and drive rolls mean that even the most dedicate products will be handled gently. At the same time, non-slip positive drive eliminates the possibility of tracking problems.

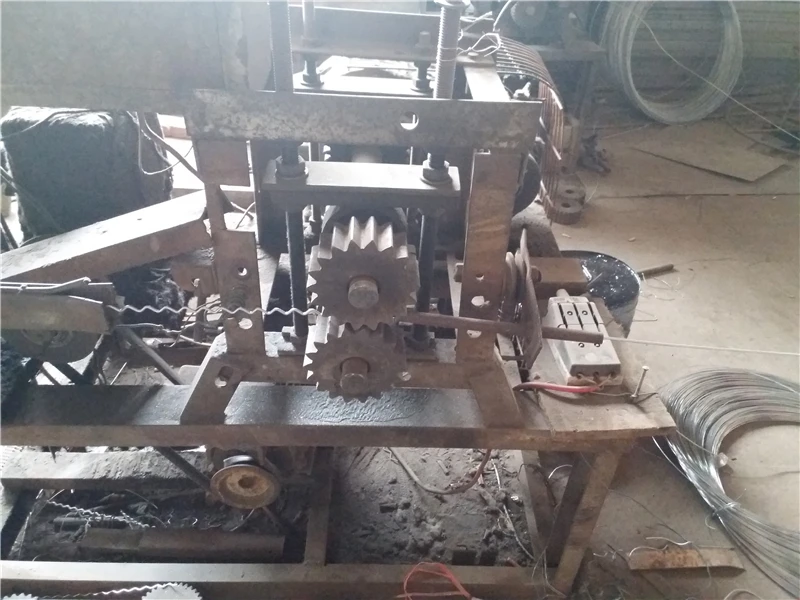

Workshop: