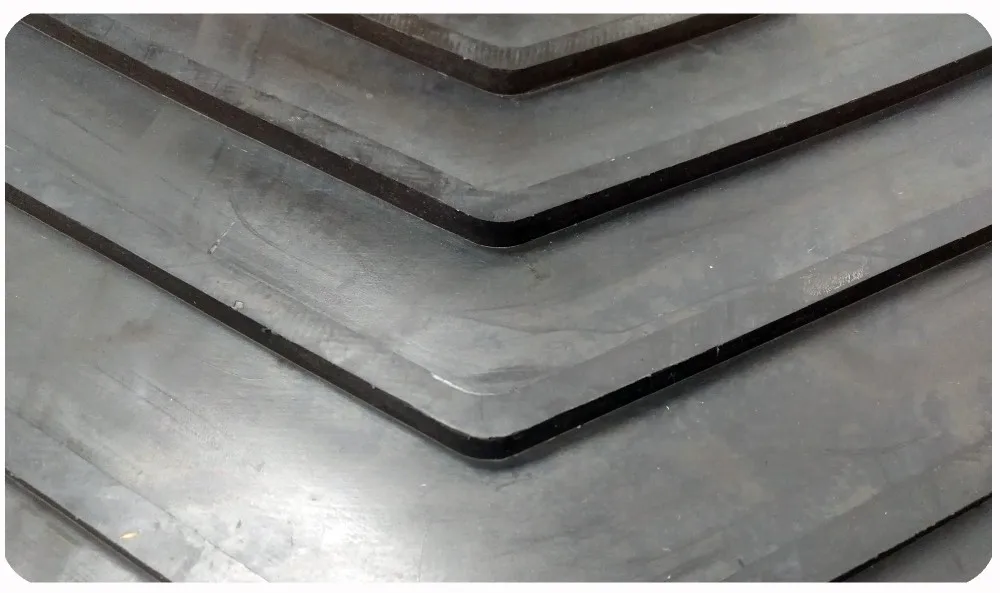

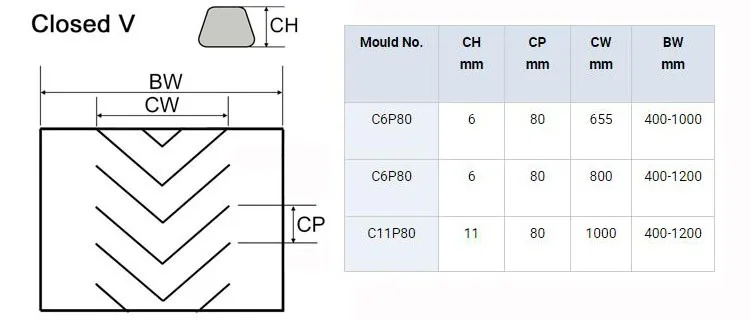

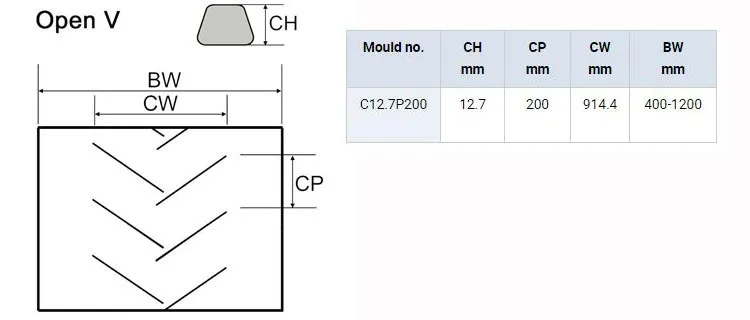

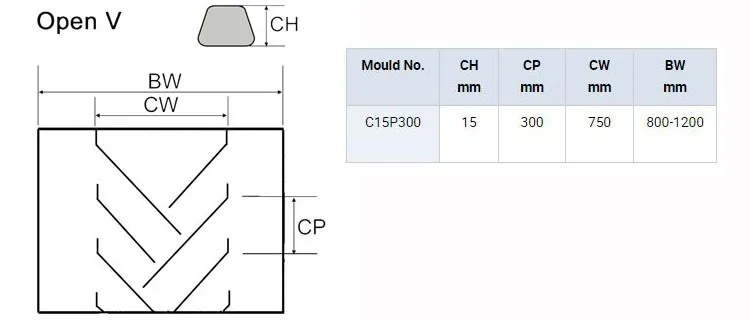

Rubber chevron profile conveyor belt with cleat of open V and closed V

Ribbed chevron profile conveyor belt

chevron profile conveyor belt are used on slope angles up to approx. 30º for slightly rolling materials such as gravel and coal and up to approx. 40º for sticky materials such as wet sand and earth.

Property

— For steep angle conveying with incline less than 45º

— Allows the use of smaller pulley diameters.

— Cleat height range from 5mm to 25mm which is suitable to convey bulk material up to 80mm lump size.

— Allows the use of smaller pulley diameters.

— Cleat height range from 5mm to 25mm which is suitable to convey bulk material up to 80mm lump size.

Property

— Available in several high quality covers including abrasion, heat, fire, oil and fat resistant.

— chevron profile conveyor belt widths range from 400 up to 1200 mm

— chevron profile conveyor belt widths range from 400 up to 1200 mm

Property

— The chevron profile conveyor belt cleats are moulded and vulcanized in one single process together with the base belt of patterned conveyor belts.

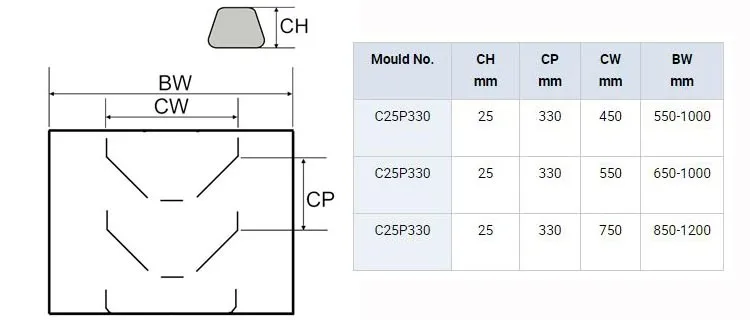

Specification

| Mould No. | CH mm | CP mm | CW mm | BW mm |

| C5P230 | 5 | 230 | 260 | 360-1000 |

| C5P230 | 5 | 230 | 300 | 400-1000 |

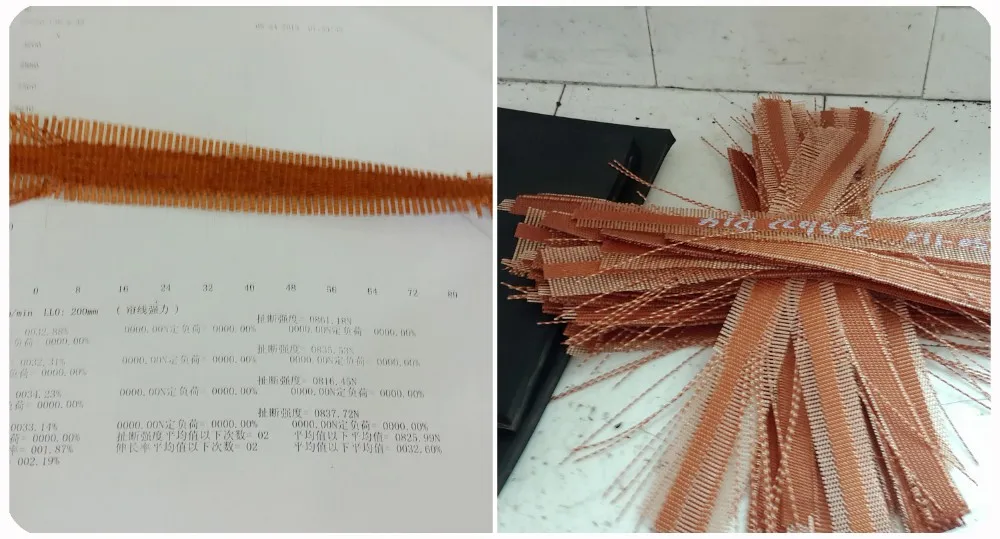

Quality control

Step 1: Raw material inspection

Rubber compound test

Moving die rheometer analyzes the characteristics of Rubber Compound

EP fabric test

Tensile strength test and elongation test when broken.

Step 2: Advance equipment to guarantee quality from the details

Calender process

4 rollers celender machine is able to stick rubber on both side of the fabric in one time.This can reduce the strength loss of the rubber during the process.

Forming process

The forming tension is even between different plies,which can avoid wrinkled fabric and guarantee an even thickness of belt core.

Step 3:Finished belts inspection

We have an inspection team to inspect the surface and dimension of each conveyor belt. If any problem on belt surface, we will repair at once in our factory.

Length and surface inspection

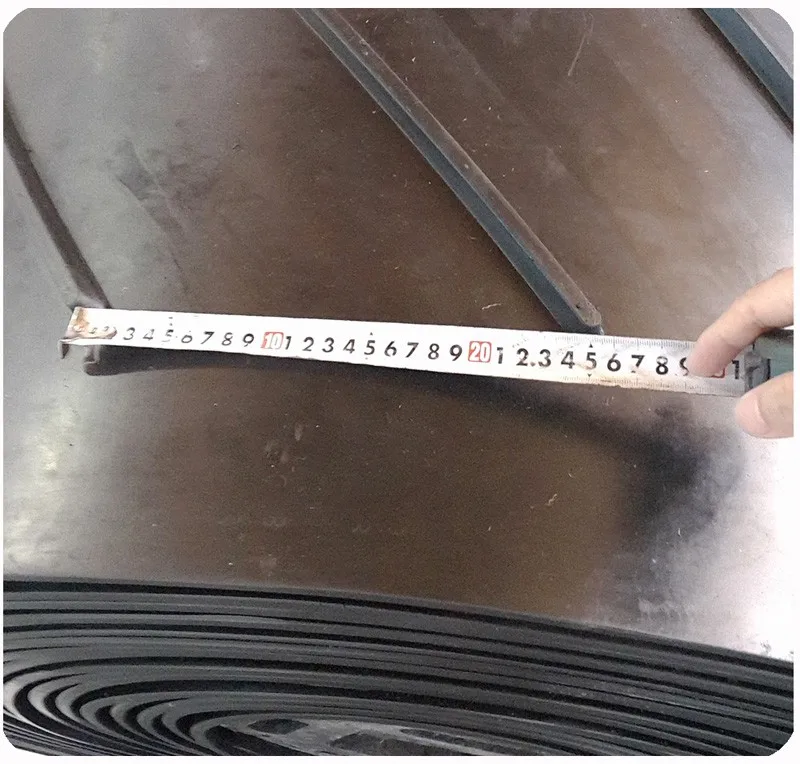

Thickness inspection

Width inspection

Step 4: Technical data test

We have a lab to test all raw materials and rubber compound.For each roll of conveyor belt,the lab will test the following features, and issue Quality Test Report.

Abrasion test

Adhesion strength test

Tensile strength test

Specifications of rubber conveyor belt

| Belt type

| Fabric type

| Single Fabric strength (N/mm)

| Rubbercover thickness (mm)

| Ply

| Belt width (mm)

| |

| Top rubber | Bottom rubber | |||||

| Cotton Canvas (CC) conveyor belt | CC-56 | 56 | 3.0 4.5 6.0 | 1.5 3.0 6.0 | 2-10 | 300-2500 |

| Nylon (NN)/Polyester(EP) conveyor belt | NN/EP-100 | 100 | ||||

| NN/EP-125 | 125 | |||||

| NN/EP-150 | 150 | |||||

| NN/EP-200 | 200 | |||||

| NN/EP-250 | 250 | |||||

| NN/EP-300 | 300 | |||||

| NN/EP-400 | 400 | |||||

| NN/EP-500 | 500 | |||||

| NN/EP-600 | 600 | |||||

Technical Standard of rubber conveyor belt

| Adhesion & Elongation of the Belt | |||||

| Belt Carcass | Adhesion | Elongation | |||

| Between Plies N/mm | Between Rubber and Carcass | Longitudinal Elongation at Break %>= | Longitudinal Elongation at Referenc Load %<= | ||

| Rubber thickness <=1.5mm | Rubber thickness >1.5mm | ||||

| Cotton | >=3.2 | >=2.1 | >=2.7 | 10 | 4 |

| NN | >=4.5 | >=3.2 | >=3.5 | 10 | 4 |

| EP | >=4.5 | >=3.2 | >=3.5 | 10 | 4 |

| Longitudinal Tensile Strength of Rubber Cloth (per ply) N/mm

| |||||

| Cotton

| NN | EP | |||

| CC | 100—500 | NN100 | >=98 | EP100 | >=98 |

| NN150 | >=147 | EP150 | >=147 | ||

| NN200 | >=196 | EP200 | >=196 | ||