Carbon Steel V-Groove Conveyor Rollers: The Versatile and Durable Solution for Your Material Handling Needs

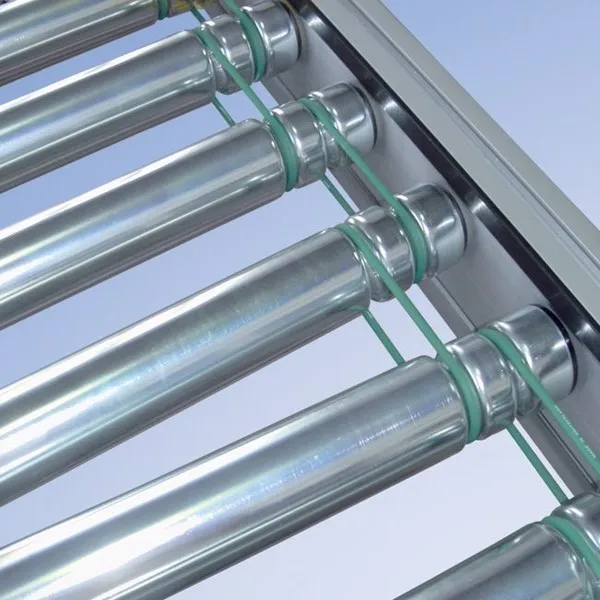

Carbon steel v groove conveyor roller If you’re looking for a reliable and cost-effective solution for your material handling needs, look no further than carbon steel V-groove conveyor rollers. These rollers are designed to handle heavy loads and provide smooth and efficient conveyance of materials in a variety of applications, from manufacturing and distribution to mining and agriculture.

Made of high-quality carbon steel, these rollers are built to last and withstand the rigors of industrial environments. They feature a V-shaped groove in the center, which helps to guide and align the materials being conveyed, reducing the risk of jamming or misalignment. The groove also allows the rollers to handle tapered or cylindrical objects, making them a versatile choice for a wide range of materials.

One of the key advantages of carbon steel V-groove conveyor rollers is their low friction and high load-bearing capacity. This means they require less energy to move materials, reducing wear and tear on the conveyor system and improving overall efficiency. They are also resistant to corrosion and wear, ensuring long-lasting performance and low maintenance requirements.

At Monster Belting, we offer a wide range of carbon steel V-groove conveyor rollers to meet your specific needs. Our rollers come in a variety of sizes and configurations, and can be customized to match your conveyor system requirements. Whether you need rollers for heavy-duty applications or for delicate materials, we have the expertise and experience to provide the right solution for you.

In addition to our high-quality products, we also offer excellent customer service and support. Our team of experts can help you select the right rollers for your application, and provide advice on installation, maintenance, and troubleshooting. We are committed to your satisfaction and success, and strive to exceed your expectations every step of the way.

Carbon steel V-groove conveyor rollers are a versatile, durable, and cost-effective solution for your material handling needs. With their low friction, high load-bearing capacity, and resistance to wear and corrosion, they are a reliable choice for a wide range of applications. Contact us at Monster Belting today to learn more about our products and services, and let us help you find the right solution for your business.

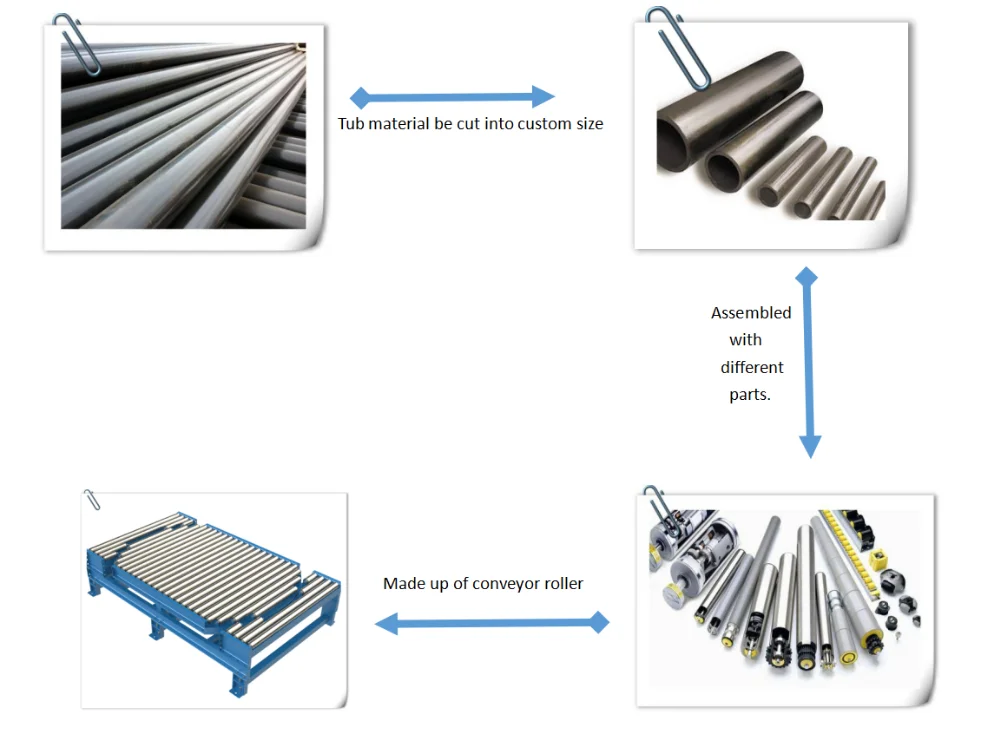

Product Description

| Product Name | |

| Color | Zinc,chrome, rubber coated with different colors |

| Brand name | Monster belt |

| Diameter | D38,D50,D60,Customized |

| Shaft(d) | D12, D15, D11hex, customized |

| Key word | Roller, conveyor roller, conveyor roller assembly, conveyor roller China manufacturing, coveyor roller design, conveyor roller replacement, v guide conveyor roller. |

| Material | Carbon steel,stainless steel,aluminium alloy |

| Application | Transportation, Machinery and electronics industry. Post and telecommunications,etc.. |

| Charater | Double groove, ajustable, accumulate transport, low noise, high speed. |

| Bearing type | Precision bearing |

| Loading capacity | Light/mid/heavy-duty, customized. |

| Finished | Galvanized, chromeplate, rubber coated |

Carbon steel v groove conveyor roller normal bearing :

| Model Number | Belt Width (mm) | Capacity (t/h) | Belt Speed (m/s) | Pulley Diameter (mm) | Motor Power (kW) | Tensioning Device |

|---|---|---|---|---|---|---|

| B500 | 500 | 40~80 | 1.3~1.6 | 500 | 1.5~3 | Screw |

| B650 | 650 | 80~120 | 1.3~1.6 | 500 | 3~4 | Screw |

| B800 | 800 | 120~200 | 1.3~2.0 | 630 | 4~5.5 | Screw |

| B1000 | 1000 | 200~320 | 1.3~2.0 | 630 | 5.5~7.5 | Hydraulic |

| B1200 | 1200 | 290~480 | 1.3~2.0 | 630 | 7.5~11 | Hydraulic |

Spring loading.

The flexible shaft roller is easy to install and disassemble, and the frame is connected with the pull rod to increase the strength.

Internal thread.

The internal thread roller is used bolt to connect the roller directly to the frame, saving the pull rod of fuselage and the stability of the whole machine.

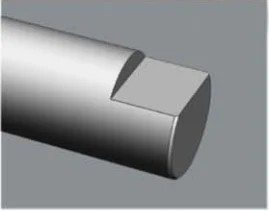

Flat tenon.

The flat tenon roller is often used for the trough belt conveyor. The rack is symmetrical and the drum can be assembled directly in the groove , as well as removed directly from the slot when disassembling.

External thread. Pin hole. Half flat tenon.

Products Show – Carbon steel v groove conveyor roller

| Model | Tube Diameter (mm) | Tube Thickness (mm) | Shaft Diameter (mm) | Bearing Type | Standard Length (mm) |

|---|---|---|---|---|---|

| CVC-CR-D50 | 50 | 1.5 | 20 | Deep Groove Ball Bearing | 170, 190, 210, 230, 240, 250, 270, 280, 290, 300, 310, 330, 350, 380, 400, 450, 500, 530 |

| CVC-CR-D60 | 60 | 2.0 | 20 | Deep Groove Ball Bearing | 170, 190, 210, 230, 240, 250, 270, 280, 290, 300, 310, 330, 350, 380, 400, 450, 500, 530 |

| CVC-CR-D63.5 | 63.5 | 2.0 | 20, 25 | Deep Groove Ball Bearing | 190, 210, 240, 250, 260, 270, 280, 290, 300, 310, 330, 350, 380, 400, 450, 500, 530, 550, 600, 650, 700, 750, 800 |

| CVC-CR-D76 | 76 | 2.0, 2.5 | 20, 25, 30 | Deep Groove Ball Bearing | 190, 210, 240, 250, 260, 270, 280, 290, 300, 310, 330, 350, 380, 400, 450, 500, 530, 550, 600, 650, 700, 750, 800, 850, 900 |

| CVC-CR-D89 | 89 | 2.5, 3.0 | 25, 30, 35 | Deep Groove Ball Bearing | 190, 210, 240, 250, 260, 270, 280, 290, 300, 310, 330, 350, 380, 400, 450, 500, 530, 550, 600, 650, 700, 750, 800, 850, 900 |

Double V groove rollers: