High quality Raw edge Cogged Fan V belt

Raw edge Cogged Fan V belt Property

— Greater power transmission than classical v belts

— Suitable for highest loads

— Temperature range from -50℃ to 120℃

— Static conductive to ISO1813

— Oil,heat,Ozone and abrasion resistant

Structure

Outside fabric: Polyester cotton canvas

Reinforcement: Polyester cord

Rubber: CR

Applications

— Pumps

— Fans

— Blenders

— Milling plants

— Drilling machines

— Autos

— HVAC systems

— Compressors

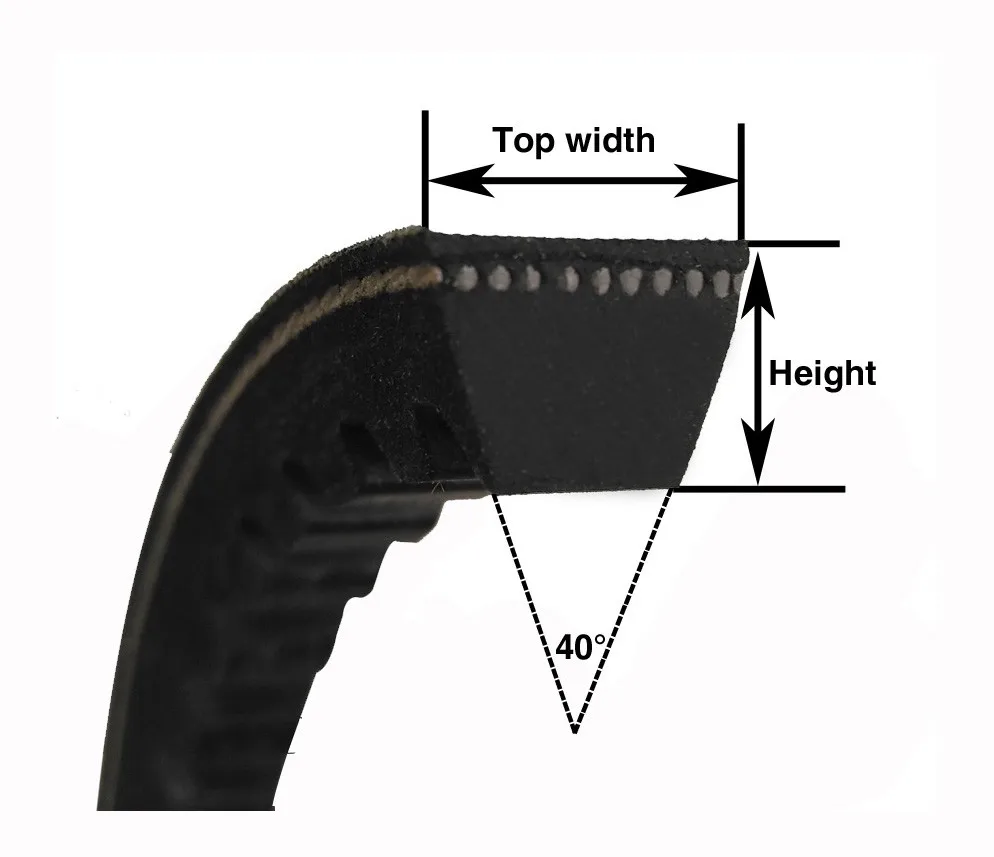

Specification

| Type | Top width | Height | Angle |

| mm | mm | 40° | |

| AVX10 | 10 | 8 | 40° |

| AVX13 | 13 | 9 | 40° |

| AVX15 | 15 | 9 | 40° |

| AVX17 | 17 | 11 | 40° |

| AVX22 | 22 | 13 | 40° |

| XPZ | 10 | 8 | 40° |

| XPA | 13 | 10 | 40° |

| XPB | 17 | 14 | 40° |

| XPC | 22 | 18 | 40° |

| 3VX | 9.5 | 8 | 40° |

| 5VX | 16 | 13.5 | 40° |

| 8VX | 25.4 | 23 | 40° |

Type and Size of Classical V Belt

| V-belt Type | Top Width | Pitch Width | Height | Length | Length Range | Length Range | Reinforcement | Angle |

| Conversion | (inch) | (mm) | Body | 40° | ||||

| O | 10 | 8.5 | 6 | lw=Li+25 | 15″-99″ | 380-2514 | 7*4N*3 | 40° |

| A | 13 | 11 | 8 | lw=Li+33 | 19″-163″ | 480-4139 | 7*4N*3 | 40° |

| B | 17 | 14 | 11 | lw=Li+43 | 25″-360″ | 630-9159 | 8*5N*3 | 40° |

| C | 22 | 19 | 14 | lw=Li+62 | 49″-479″ | 1256-12160 | 9*9N*3 | 40° |

Type and Size of V Ribbed Belt/Poly V Belt

| Type | Rib Section | Angle of Rib | Belt Width | Belt Thickness | Rib Number | Length Range |

| 3PK | 3.56 | 40 | 10 | 4.8 | 3 | 500-5000mm |

| 4PK | 3.56 | 40 | 13.6 | 4.8 | 4 | 500-5000mm |

| 5PK | 3.56 | 40 | 17 | 4.8 | 5 | 500-5000mm |

| 6PK | 3.56 | 40 | 20.7 | 4.8 | 6 | 500-5000mm |

| 7PK | 3.56 | 40 | 24.3 | 4.8 | 7 | 500-5000mm |

| 8PK | 3.56 | 40 | 27.8 | 4.8 | 8 | 500-5000mm |

| 9PK | 3.56 | 40 | 31.4 | 4.8 | 9 | 500-5000mm |

| 10PK | 3.56 | 40 | 35 | 4.8 | 10 | 500-5000mm |

| 12PK | 3.56 | 40 | 42.5 | 4.8 | 12 | 500-5000mm |

| 15PK | 3.56 | 40 | 53 | 4.8 | 15 | 500-5000mm |

Structure of V Belt Raw edge Cogged Fan V belt

| Function | Material | |

| Tension Member | The treated polyester cord is a low stretch high strength tension member able to withstand shock loads on drives with fixed centers | Polyester/Aramid Fiber |

| Rubber Ribs | Long wearing, oil resistant, fibre-loaded neoprene rubber is used in the ribs to provide support for the tension member and to transmit the loads to the pulley | NR,CR,EPDM |

| Backing Material | Bias ply type fabric backing resists cracking and provides abrasion resistance | NR,CR,EPDM |

| Insulation Material | oil and heat resistant rubber is used to bond the tension member to the rest of the belt | NR,CR,EPDM |